Welcome Aboard the Prohull Asia Blog: Navigating the Seas of Value Engineering!

Shipbuilding is a complex process that requires a high level of precision and expertise. Even the slightest error during construction can lead to a catastrophic failure, resulting in damage to the vessel, loss of life, and environmental hazards. This is why inspection is an essential aspect of shipbuilding that can prevent disasters and ensure the safety of ships and their crew.

Inspection during shipbuilding involves examining various aspects of the vessel, including the hull, machinery, and electrical systems. This process ensures that each component meets the required standards and specifications and that any issues are identified and addressed before the ship is put into service.

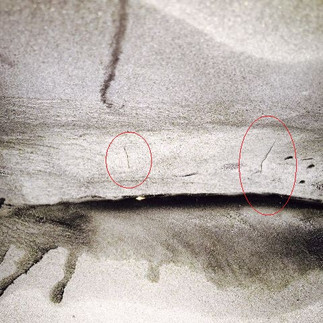

One critical area of inspection in shipbuilding is welding. Welding is used extensively in shipbuilding to join different vessel components, including the hull, deck, and superstructure. However, welding defects such as cracks, porosity, and incomplete penetration can weaken the ship's structure, leading to catastrophic failures.

Welding inspection involves visual inspection, radiography, ultrasonic testing, magnetic particle inspection, and dye penetrant inspection. These techniques detect welding defects and ensure the welds meet the specified requirements.

Dirty electrodes, poor welding techniques and significant gaps increase the possibility of failures (Copyright ©, 2023)

Another critical area of inspection in shipbuilding is the machinery and electrical systems. The machinery and electrical systems of the ship are responsible for its propulsion, power generation, and operation. Any defects in these systems can lead to the failure of critical equipment and the failure of the vessel.

Inspection of the machinery and electrical systems involves testing components such as engines, generators, pumps, and control systems. The inspection ensures that each component meets the required specifications and is in good working condition. This process also identifies potential issues, allowing them to be addressed before they cause problems during operation.

Main engine alignment and measuring the bearing loads of the engine main bearings,

the intermediate shaft bearings, forward stern tube bearing in a static condition, Fuel Oil and Main LO system flushing and other inspections of machinery and systems ensure that each component, system and design meets the required specification.

(Copyright ©, 2023)

In addition to these areas, inspection during shipbuilding also includes examining materials, coatings, and safety equipment. Each of these areas plays a critical role in the safety and reliability of the vessel. Any defects or issues must be identified and addressed before the ship is put into service.

In conclusion, inspection is a critical aspect of shipbuilding that can prevent disasters and ensure the safety of ships and their crew. Inspection of welding, machinery, electrical systems, materials, coatings, and safety equipment ensures that each component meets the required specifications and is in good working condition. By identifying and addressing any issues during construction, an inspection ensures that ships are safe and reliable, reducing the risk of catastrophic failures and disasters.

COPYRIGHT WARNING AND INFORMATION: For requests to use copyright-protected work in any manner, email prohullasia@prohullasia.com

Comments